Showroom

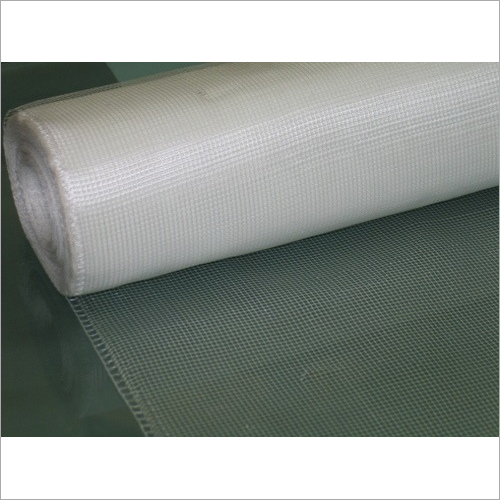

The provided fiberglass fabric is a general kind of fiber-reinforced plastic that is made by using glass fiber. In addition, the fibers can be randomly organized, woven into a cloth or flattened into a sheet .

The plastic matrix of our fiberglass tape can be a thermoset polymer blend that is most frequently based on thermosetting polymers, for example, thermoplastic, vinylester, polyester resin orepoxy.

The provided chop strand mat is utilized by numerous customers for skin covers on gelcoats. It is also utilized as a Finish fabric over different Stitch Mats and reinforcements.

This fiberglass sleeving is broadly utilized in air as well as liquid transmission in food and medical industries. It can endure 200 degree temperature. This is approved by FDA and is of medical grade.

The delivered fiberglass roving is additionally known as chop strand and woven roving, which is composed from ceaseless glass fiber roving that are interlaced into hefty weight fabrics. It is also compatible with various resin systems.

Just like cotton and wool, fiberglass yarn produced from fiberglass can be woven into fabric. Our company supplies the yarn wound on different sizes of bobbin. It can go through processes, like knitting, braiding, weaving, warping and more.

|

KRIPA INTERNATIONAL (INDIA)

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese